Introduction

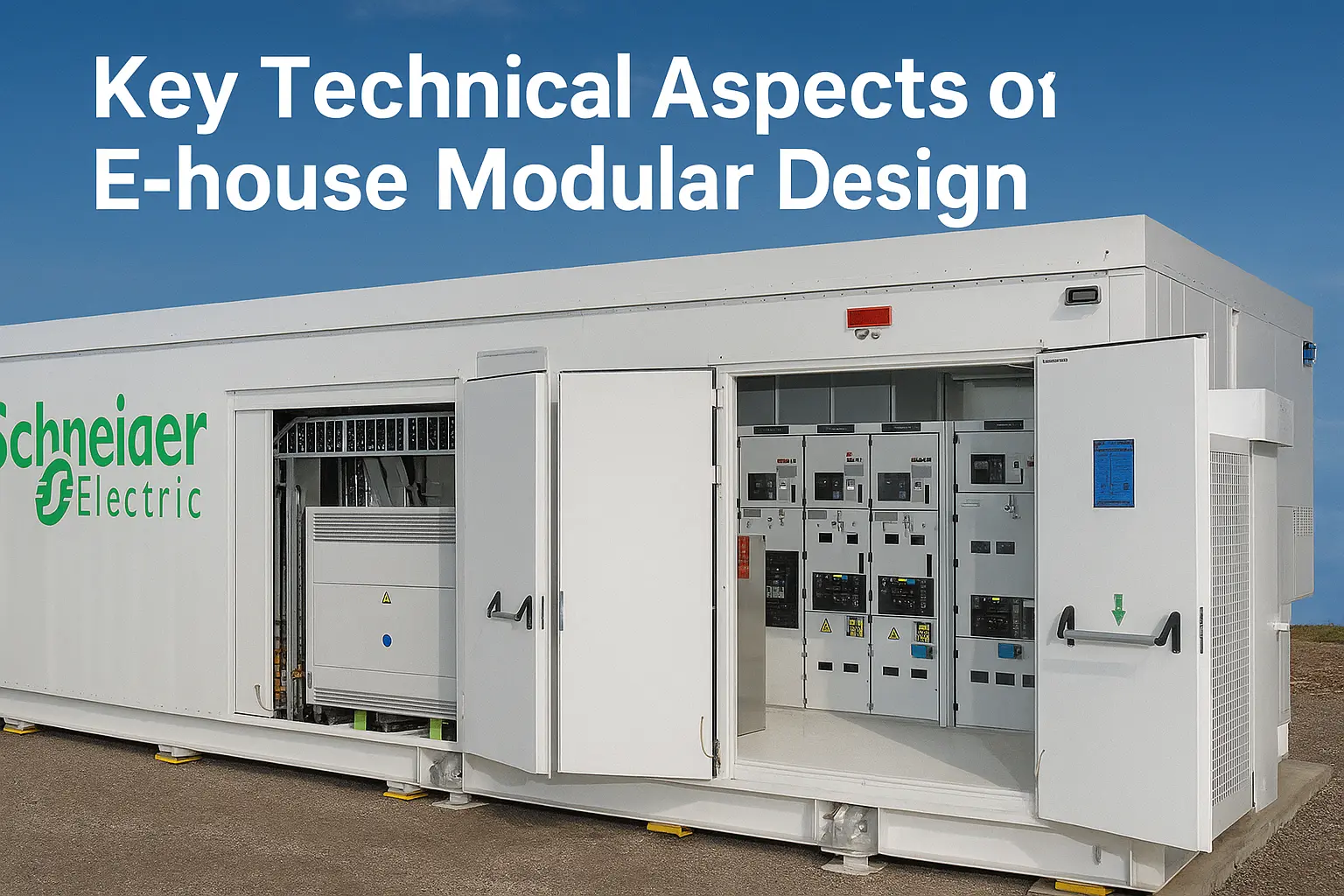

In recent years, prefabricated E-houses — also known as electrical houses, power control centers, or modular substations — have played an increasingly important role in modern industrial and infrastructure projects. Compared with traditional concrete substations and electrical rooms, E-houses offer faster deployment, better mobility, reduced on-site construction work, and a high level of integration for power distribution and automation systems.

As global industries continue to move toward digitalization, renewable energy, electrification, and smart infrastructure, the applications and technical standards for E-houses are evolving rapidly. From mining and oil & gas fields to data centers, utilities, ports, and renewable power plants, E-houses are becoming a strategic solution for reliable, scalable, and intelligent power supply systems.

This article explores the future development trends of E-houses, analyzing technology evolution, engineering design concepts, industry drivers, and application scenarios — and what these changes mean for end users, EPC contractors, and project developers.

What is an E-house?

An E-house is a modular prefabricated building that integrates electrical and automation equipment inside a factory-assembled enclosure. It typically includes:

-

Medium-voltage switchgear

-

Low-voltage switchgear and MCC

-

Protection relays and automation systems

-

SCADA, communication, and monitoring devices

-

Power transformers or UPS (depending on configuration)

-

HVAC, fire protection, lighting, and auxiliary systems

Instead of building a concrete electrical room on site, the entire system is designed, assembled, wired, and tested in a factory. The completed module is then shipped to the project site as a plug-and-play power supply solution.

Key Advantages of E-house Solutions

-

Shorter construction and commissioning cycles

-

Reduced civil engineering work

-

Better quality control through factory assembly

-

Modular and scalable layout

-

Easier relocation and expansion

-

Lower overall lifetime costs

-

Standardized design and repeatable project models

With growing pressure on project timelines and investment efficiency, these benefits will continue to drive global demand for E-house systems.

Trend 1: Modularization and Standardized Engineering

One of the most significant future trends in E-house development is the shift toward modular and standardized engineering.

Traditional E-houses were often customized for each project, resulting in lengthy design cycles, limited interchangeability, and complex logistics. Today, more manufacturers and EPC partners are moving toward:

-

Standardized E-house platform designs

-

Modular structural dimensions

-

Repeatable electrical configurations

-

Flexible expansion interfaces

This approach enables:

-

Faster engineering approval

-

Reduced material and fabrication cost

-

Easier international transportation

-

Simplified on-site installation

-

Consistency in performance and reliability

Platform-based E-house Design

Future E-house systems will increasingly follow a platform-based design model, similar to modular product architecture in industrial manufacturing.

Typical platform modules may include:

-

MV switchgear compartment module

-

LV switchboard / MCC module

-

Automation & control module

-

Battery / UPS module

-

Renewable integration module

-

Auxiliary support module

Instead of redesigning from scratch, engineers can configure solutions using predefined module combinations. This helps accelerate delivery — especially in large-scale industrial and utility projects.

Trend 2: Digitalization and Smart Monitoring

As industries adopt smart grid technologies and digital asset management, E-houses are evolving into intelligent energy management nodes rather than simple power distribution units.

Future E-house designs will feature enhanced digital capabilities such as:

-

Online condition monitoring

-

IoT-enabled smart sensors

-

Cloud-connected SCADA platforms

-

Asset health diagnostics

-

Remote operation & maintenance tools

-

Predictive maintenance analytics

From Passive Equipment to Active Data Hubs

Smart E-houses will become:

Data-driven infrastructure assets that support operational decision-making and lifecycle optimization.

Examples include:

-

Real-time temperature, humidity, and vibration monitoring

-

Electrical parameter analytics and fault recording

-

Switchgear breaker health prediction

-

Remote firmware upgrades

-

Cyber-secure communication networks

This trend is particularly valuable for:

-

Remote mining and oil fields

-

Offshore facilities

-

Renewable power stations

-

Harsh environmental locations

where on-site maintenance resources are limited.

Trend 3: Integration with Renewable Energy and Microgrids

Global energy systems are transitioning toward renewable power and distributed energy resources. As a result, future E-houses will increasingly support:

-

Solar and wind farm substations

-

Battery energy storage systems (BESS)

-

Hybrid microgrid power systems

-

Grid-tie and island operation modes

This development requires:

-

Advanced protection & coordination schemes

-

Higher levels of automation

-

Energy management interfaces

-

Bidirectional power flow capability

E-house as the Core of Microgrid Infrastructure

In many remote regions, off-grid or weak-grid areas rely on:

-

Diesel generators

-

PV arrays

-

Wind turbines

-

Battery storage systems

E-houses can function as the:

-

Central control room

-

Power conversion center

-

Protection and switching hub

enabling reliable and efficient microgrid operation.

As global sustainability policies accelerate, renewable-ready E-house solutions will become a mainstream engineering trend.

Trend 4: Higher Safety, Reliability, and Compliance Standards

Future development of E-houses will also focus on enhanced safety, durability, and international compliance.

Engineering designs are expected to prioritize:

-

Fire and arc-flash risk mitigation

-

Improved structural strength

-

Higher ingress protection ratings

-

Seismic and wind-load resistance

-

Enhanced personal safety measures

Depending on application regions, E-house systems may involve:

-

IEC and IEEE standards

-

UL / CSA certification for North America

-

Utility and grid-specific requirements

-

Special industrial safety norms

Application-Specific Engineering Adaptations

Typical scenarios include:

-

Desert high-temperature environments

-

Offshore and coastal salt-spray conditions

-

Cold-climate operation

-

Chemical or hazardous areas

Future E-house solutions will adopt:

-

Specialized insulation materials

-

Corrosion-resistant coatings

-

Reinforced structural modules

-

Environmental-grade ventilation and sealing

This evolution ensures long-term performance stability and reduces lifecycle risk for project owners.

Trend 5: Faster Deployment and Project Delivery Models

Project development cycles are becoming shorter — especially in:

-

Data center construction

-

Renewable power projects

-

Emergency expansion facilities

-

Temporary industrial sites

E-houses naturally align with these market needs.

Future project models will increasingly adopt:

-

EPC + Prefabricated Modular Delivery

-

Off-site factory assembly and FAT testing

-

Plug-and-play on-site integration

This reduces:

-

On-site construction time

-

Labor and logistics constraints

-

Commissioning complexity

-

Project cost uncertainty

Factory-Integrated System Testing

A key trend is the expansion of:

Full system functional testing before shipment.

This includes:

-

Control logic verification

-

Protection relay testing

-

Communication system integration

-

Power system interlocking checks

By verifying performance in the factory, project risk is significantly reduced, and on-site commissioning becomes smoother and safer.

Trend 6: Lifecycle Service and Remote Technical Support

As E-house systems become more intelligent, service models are also evolving toward long-term lifecycle partnerships rather than one-time equipment delivery.

Future service offerings are expected to include:

-

Remote performance monitoring

-

Lifecycle health assessment reports

-

Spare parts and component upgrade plans

-

Remote troubleshooting assistance

-

Periodic technical inspection services

This approach helps customers:

-

Extend equipment lifespan

-

Reduce unplanned downtime

-

Optimize operating costs

-

Improve asset availability

For global project owners and EPC partners, strong lifecycle service capability will become a key factor when selecting E-house suppliers.

Trend 7: Expansion into More Industrial Application Scenarios

With growing engineering maturity and technology innovation, E-house applications will continue to expand across industries such as:

-

Mining and minerals processing

-

Oil & gas fields

-

Ports and logistics hubs

-

Data centers

-

Renewable power plants

-

Rail and transportation

-

Utilities and smart grids

-

Large industrial facilities

Each sector presents different functional priorities — for example:

-

Mining projects value mobility and ruggedness

-

Data centers require high reliability and fast deployment

-

Renewable power plants emphasize scalability and system integration

Future E-house solutions will become increasingly application-oriented, offering optimized configurations tailored to each industry’s operating characteristics.

Sustainable Design and Environmental Considerations

Sustainability is another major direction shaping the future of E-house systems.

Manufacturers and project developers are paying closer attention to:

-

Energy-efficient HVAC systems

-

Environmentally friendly materials

-

Reduced construction waste

-

Reusable modular structures

-

Lower carbon footprint across the lifecycle

Because E-houses are prefabricated, they naturally reduce:

-

On-site environmental disturbance

-

Heavy civil construction activity

-

Waste material handling

In the long term, sustainable engineering will strengthen the competitiveness of E-house solutions in global infrastructure development.

The Strategic Role of E-house in Future Power Infrastructure

Looking ahead, E-houses will not only serve as electrical equipment shelters, but as:

-

Smart power system integration platforms

-

Digital infrastructure control nodes

-

Scalable and mobile energy centers

-

Strategic components of modern industrial development

They will continue to support:

-

Fast-growing emerging markets

-

Smart manufacturing and industrial automation

-

Renewable and distributed energy systems

-

Global infrastructure modernization

For project developers, EPC contractors, and end users, selecting the right E-house partner — with strong design, manufacturing, testing, and service capabilities — will be essential to project reliability and long-term operational value.

Why Choose FATENG ELECTRIC for E-house Solutions

At FATENG ELECTRIC, we focus on providing high-quality, engineering-driven E-house solutions for global customers. Our capabilities include:

-

Independent design and modular engineering

-

Factory prefabrication and integrated system assembly

-

Complete functional testing before delivery

-

Support for OEM / ODM customization

-

Flexible component brand selection

-

Global technical support and after-sales service

Our E-house products are widely used in:

-

Industrial facilities

-

Overseas infrastructure projects

-

Energy and utility sectors

-

Renewable and microgrid applications

We are committed to delivering reliable, efficient, and future-ready E-house solutions that help our partners accelerate project implementation and reduce lifecycle costs.

Conclusion

The future development trends of E-houses are driven by global industrial transformation, sustainable energy transition, and digital technology innovation. Modular engineering, smart monitoring, renewable integration, safety enhancement, and lifecycle service will continue to shape the evolution of E-house solutions worldwide.

As markets demand faster deployment, higher reliability, and greater flexibility, E-houses will play an increasingly important role in modern power infrastructure.

FATENG ELECTRIC will continue to work closely with partners around the world, providing advanced E-house solutions that support future-oriented industrial and energy development.